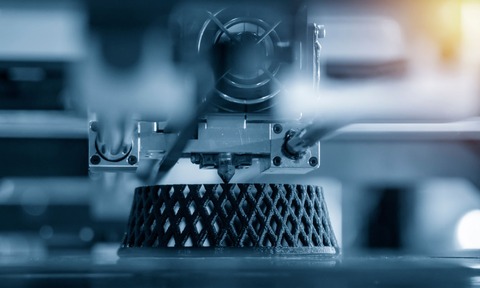

The biomedical sector is emerging as a key arena for 3D printing technologies, enabling researchers to access new tools to tackle design challenges, explains Ricky Wildman.

It’s now been in existence for over 30 years, but 3D printing’s innovation continues unabated. At the University of Nottingham, we have been exploring its use in life sciences, looking at how it can be used to make people’s lives better, from the design of prosthetics for children to the manufacturing of drug delivery systems that can be tailored exactly to patient needs. We are not the only ones – according to Precedence Research [1] the global mark et size of biomedical 3D printing is expected to rise by almost $5 billion by 2030.

When we first started, 3D printing was mostly used for prototyping and it was frequently limited in resolution, restricted to feature sizes above 100 microns. What we have seen, however, is that over the last 10-15 years, the technology has improved considerably, with it now being thought of as a manufacturing technology rather than a prototyping solution, and there has been a universal push towards higher resolution.

Improvements in resolution have many advantages. For example, in bioprinting it means that we can manufacture at length scales that biological cells work at. In other applications, it provides precision, so that personalised drug delivery devices work even better. More recently in our labs we started to consider how high-resolution 3D printers could be used to support process technologies, such as reactors or mixers.

Improvements in resolution have many advantages. For example, in bioprinting it means that we can manufacture at length scales that biological cells work at. In other applications, it provides precision, so that personalised drug delivery devices work even better

We started to use projection micro stereolithography; in our laboratory we have both a Boston Micro Fabrication S240 and S130, enabling us to reliably manufacture down to 10 microns and two microns respectively. For us this is important, since in process technologies, mass (or sometimes energy) transport matters, and being able to manufacture small, with precision, but also at scale, means we can seek solutions that offer sustainable, efficient and selective manufacturing capabilities.

Nottingham’s adoption of 3D printing

Our work in this area has been ongoing for over 10 years, but in 2023, the University of Nottingham’s Centre for Additive Manufacturing was the recipient of an Engineering and Physical Sciences Research Council (EPSRC) grant for a programme entitled ‘Dialling Up Performance for On Demand Manufacturing’. This project aimed to develop a toolkit that enables innovators to rapidly formulate materials and designs that ease the path from idea to implementation.

Our target was the pharmaceutical industry, but the toolkit would be applicable to many sectors. Together with our industry partners, including Boston Micro Fabrication (BMF) CEO John Kawola and colleagues from AstraZeneca, Pfizer and GSK, we are working to automate the identification of 3D printing materials and processes best suited for healthcare products. This research will help to move products quickly into production and aims to speed up adoption and streamline product design to treat medical conditions. For example, one product we are working on is an intestinal patch that will allow for tissue regeneration in situ, which requires 3D printing to develop the complex structures at a very small size.

In a related project, also funded by EPSRC, ‘Designing bio-instructive materials for translation-ready medical devices’, we are considering the compatibility issues of implanted medical devices. Device rejection is a dangerous and significant problem in healthcare, and we’ve found that physical surface patterns, known as topographies, help to ensure device acceptance. This work involves using BMF’s micro 3D printing technology to understand whether it’s possible to move from small scale laboratory work to production scale, without losing any of the important structural details.

Latest research

Recently, our research has focused on a highresolution 3D printed biocatalytic reactor core with optimised efficiency for continuous flow synthesis, which aims to improve performance and transport of reactants through the system. The research utilised BMF’s proprietary highresolution micro 3D printing technology to create the reactor cores, where the micro level printing allows for superior mass transport. We embedded biocatalytic enzymes into polymer hydrogel networks and performed continuous synthesis. This enabled us to show that the mass transport, and therefore the efficiency of the reaction, was significantly improved by virtue of the increased resolution available.

We found that the 3D printed parts allowed for a 60% improvement in the rate of product formation per unit of enzyme compared to structures without the channels. Under flow, the rate of product synthesis increased by 240% compared to reactions conducted without flow. These findings demonstrate that 3D printed parts enhanced the efficiency and ability to move the material through the channels, paving the way for the development of advanced, optimised flow reactors. This suggests potential for scalable, efficient and sustainable manufacturing of highvalue products in the medical space, such as pharmaceuticals. Our team continues to search for ways that 3D printing can support advances in the life sciences space through our research.

Driving breakthroughs: the future of 3D printing in life sciences research

Additive manufacturing is accelerating research, especially where there is a need for ultra-high precision and accuracy in models, such as with the reactor core. In life sciences, the technology is also being used by researchers to develop new therapies, design medical technology and personalise medical devices and treatments. Where traditional methods aren’t cutting it, 3D printing has the ability to help researchers through design challenges and prototyping processes. I’ve seen how this technology can help to improve efficiency and create new ways to solve old problems, and I look forward to seeing how researchers continue to utilise this technology to make breakthroughs in their own studies.

References:

1 https://www.precedenceresearch.com/3d-printing-inhealthcare-market

Ricky Wildman is professor in chemical engineering at the Centre for Additive Manufacturing, University of Nottingham